|

| Color Separation |

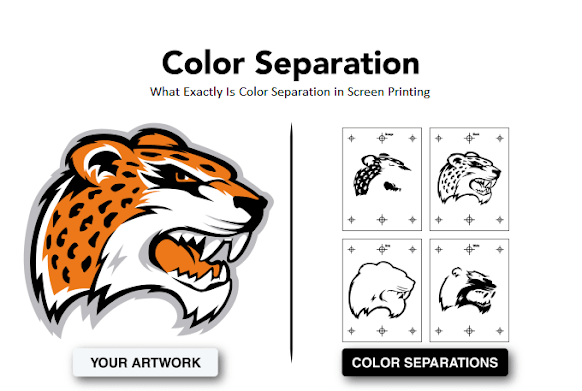

Color separation for screen printing is the technique of separating artwork or a design into different color segments. To produce a design on any object, it is necessary to first separate the colors, as this is an important aspect of screen printing. Recently, software has been developed to assist in making the entire procedure easier.

The color separation procedure's purpose is to prepare the file for printing. The image and the surface it will be printed on define the type of color separation process employed. Color separation software breaks down images into the individual elements needed to recreate them.

The color separation procedure's purpose is to prepare the file for printing. The image and the surface it will be printed on define the type of color separation process employed. Color separation software breaks down images into the individual elements needed to recreate them.

Color Separation Types:

Understanding the various types of separations and the obstacles associated with them will help you do successful separations on a regular basis. Although perfect color separation may require years of skill, screen printers can make the process much easier with the right screen printing software.

Knowing which of the processes listed below will work best for your design will assist you in achieving the best results. It is also critical to have access to trustworthy screen printing software. The following color separations are utilized in screen printing.

Spot Color Separations:

The most common separation method in screen printing is spot color separations. Spot color separations can include everything from vector conversions to raster logos to cartoon designs, with each shade printed independently with its own ink. It could entail the use of halftones for shading. Spot Colors enable more exact color manipulation while printing.

Spot color separations can have a simple or complicated appearance. Some incredibly complex designs will fit on a press and print in spot color. Spot colorwork that contains too many colors for the press can also be divided into simulated process files.

Four-Color Separations:

This color separation technology uses four colors to print an image: cyan, magenta, yellow, and black (CMYK). Printing these four tones will produce the majority of the colors in your image. In four-color process separations, halftones, or minuscule dots, are employed to create photorealistic images.

However, because the inks are translucent, it can be difficult with darker backgrounds; this process works best with white or brighter backgrounds. Because of the system's color fidelity, the spot color simulated method has replaced it as a popular separation alternative over the previous decade.

Separations in Simulated Processes:

Simulated process separations, like four-color process separations, use halftones to generate images, but the simulated process employs a larger color range to handle a wider variety of colors. Because opaque inks are used, a simulated process, unlike four-color process separations, can be used for both light and dark backgrounds.

Simulated process separations are sometimes known as tonal or channel separations. In addition, color separation photoshop is used to perform simulated-process color separations, which are equivalent to four-color process separations. Screen printing simulation is used for apparel, garments, and bespoke t-shirt printing.

Read More About : Top 10 Free Embroidery Monogram Fonts You Must Need To Follow

I appreciate your hard work. Keep posting new updates with us. This is really a wonderful post. Nice Blog Very interesting and useful information on your website. Thanks for sharing the blog and this great information which is definitely going to help us.

ReplyDeleteapsu ba 3rd year result roll number wise

Post a Comment